Our Story

We make what we love!

Nestled on the Bay, in Melbourne’s South East, Braeside Brewing Co is an independent family owned brewery and eatery. Having grown up in the area, we are excited to be serving our community- it has been a long time coming! We provide a relaxed and comfortable space to share a beverage and bite in a family-friendly atmosphere.

Collectively, the team brings +40 years of experience in the food & beverage industry and we are delighted to be showcasing our creative range of craft beers. We also have a range of Gluten Free & Non-Alcoholic beers made locally.

Accompanying your beers, is a selection of fresh stone-fired pizzas and tempting bar menu. Additionally, many of our spirits and wines are produced locally to complete your experience.

FounderRAME ABDALLAH

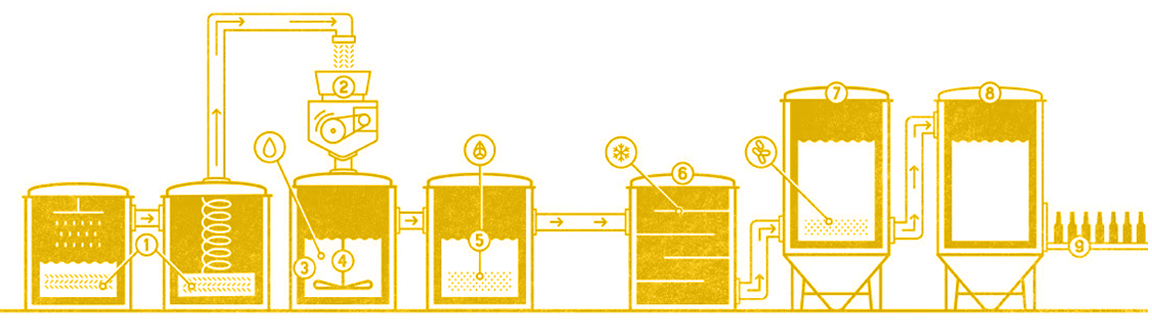

THE BREWING PROCESS

01. MALTING

Malting converts barley to malt for use in brewing. Dried grains are steeped in water and germinated before being kiln-dried to the desired colour and specification, from very pale through to crystal and amber, or to chocolate and black malts.

02. MILLING

Milling cracks the malted grains, allowing water to penetrate and be absorbed during the mashing process in order to extract sugars from the malt.

03. WATER

Beer is largely composed of water. Regional water supplies have varying mineral constituents, with some more appropriate for certain beer styles than others. For example, water from Burton-upon-Trent is famously perfect for pale ales, to such a degree that brewers will add gypsum to their local water in a process known as Burtonisation.

04. MASHING

The milled grain and water are mixed and heated in a ‘mash tun’, an insulated brewing vessel with a false bottom. This allows the enzymes in the malt to break down the insoluble starch in the grain into soluble sugars, creating a malty liquid called ‘wort’.

05. BOILING

The wort is moved into a large tank (a ‘copper’, or ‘kettle’), where it is boiled with hops, and sometimes herbs or sugars. Chemical reactions take place which determine much about the final flavour, colour and aroma. Hops are added for taste, aroma, and bitterness. At the end of the boil, the hopped wort settles to clarify in a ‘whirlpool’ vessel, where solid particles in the wort are separated out.

06. COOLING

Before yeast can be added, the wort must be brought down to a fermentation temperature of 20°-26° Celsius. Most breweries use a plate heat exchanger, with cold water running in adjacent pipes to the wort. Rapid cooling prevents oxidation and contamination.

07. FERMENTATION

After the wort is cooled and aerated, yeast is added and it begins to ferment. During this stage sugars from the malt are metabolised by the yeast, turned into alcohol and carbon dioxide, and the product can be called beer for the first time. Fermentation tanks come in various shapes, forms, and materials, from large stainless steel cylindro-conical vessels, through to open stone vessels and traditional wooden vats.

08. CONDITIONING

After initial or primary fermentation, the beer is usually transferred into a second container so that it’s no longer exposed to the dead yeast and other debris that will have settled to the bottom of the primary fermenter. The beer is ‘conditioned’ (matured or aged). Lagering takes 2-3 weeks on average but can also take months depending on the beer.

09. TAPPING

The beer can now be transferred to kegs, bottles, or cans.